At Mazza Innovation, we have developed an advanced method for bioactive extraction called the PhytoClean™ Method. PhytoClean™ is Mazza’s patented core technology that yields clean ingredients in an earth-friendly manner. PhytoClean™ employs an environmentally-responsible extraction method that applies heat and pressure to water to lower its polarity, causing it to behave like an organic solvent.

EARTH-FRIENDLY AT EVERY STEP

The PhytoClean™ Method redefines clean and green while delivering superior bioactives.

1. CLEAN INGREDIENTS

Follows an earth-friendly process that produces concentrated ingredients free of organic solvents.

2. LESS ENERGY AND WASTE

Consumes less energy than traditional extraction methods. Its by-products are non-toxic and easily composted or disposed of without harm to the environment.

3. WORKPLACE SAFE

Minimizes risk to employee health, safety, and the environment by eliminating the use of hazardous organic solvents that require environmentally-intensive operations, complicated safe-handling procedures, and specialized hazardous waste management processes.

4. OPTIMAL COMPOUND RECOVERY

Effectively isolates and extracts bioactives previously considered non-recoverable or uneconomic by conventional means.

HOW PHYTOCLEAN™ WORKS

![]()

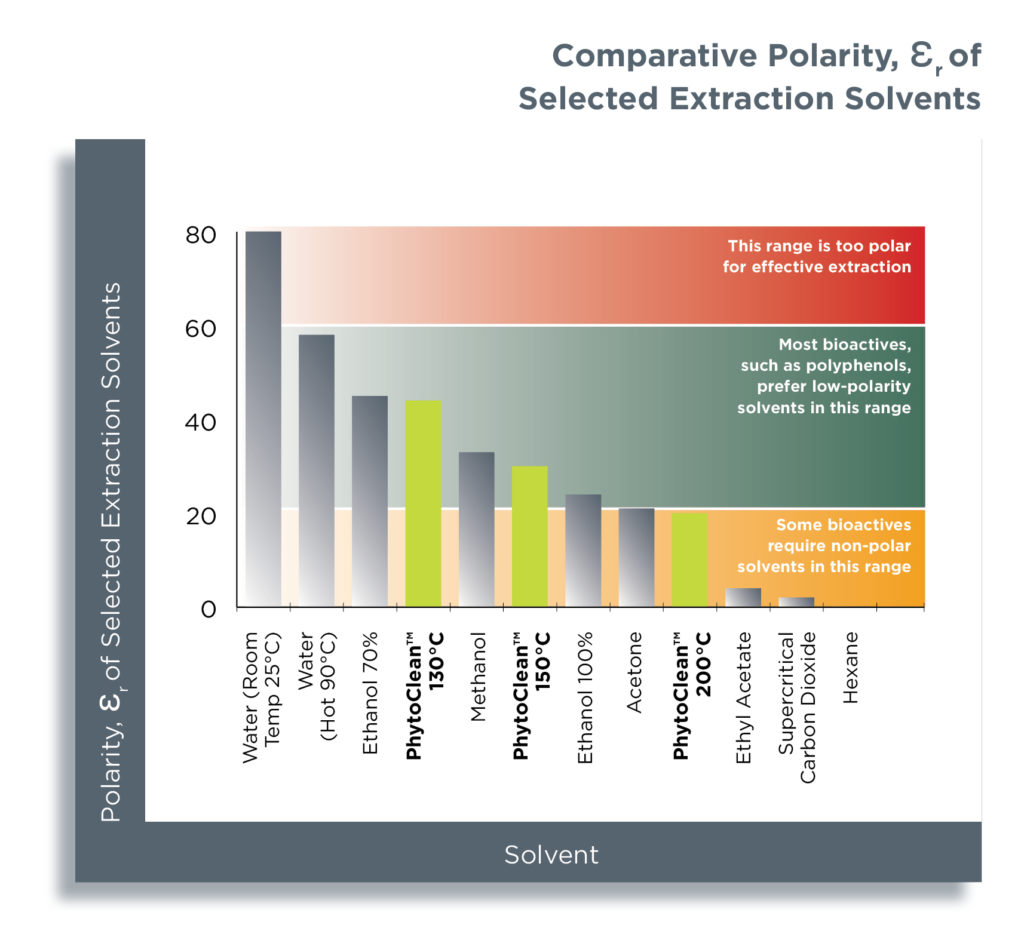

1. EXTRACTION WITHOUT ORGANIC SOLVENTS

Extraction is the unique part of who we are. Our patented PhytoClean™ Method produces concentrated bioactives from plant materials—without the need for organic solvents. By pressurizing water at elevated temperatures, the polarity of the water is lowered to the levels of ethanol. This increases the water’s ability to solubilize bioactive compounds and causes it to behave like an organic solvent. Our unique “flow-through” process pumps this pressurized low-polarity water through the plant material—berry pomace for example—to enable the efficient extraction of bioactives.

Not only does PhytoClean™ improve the dissolution properties of water, the high temperature of the water can create a reaction that breaks down plant cell walls and membranes, allowing freer access to the target compounds. Our process can unbind and extract the targeted compounds that would not be recovered with conventional organic solvent extraction methods.

![]()

2. CONCENTRATION OF EXTRACTS

After producing the raw liquid extract, the dissolved solids are concentrated by removing water in an evaporation process. This creates a liquid concentrate full of bioactive compounds that retains the original color, flavor, and aroma profile of the plant and is less prone to microbial growth.

![]()

3. DRYING TO PRESERVE BIOACTIVE COMPOUNDS

An innovative drying process further concentrates the solids by removing the remaining moisture to create stable extracts. This process produces greater than 95% solid ingredients, making them easier to handle and increasing shelf life.

![]()

4. CLEAN EXTRACTS THAT ADAPT TO YOUR APPLICATION

At Mazza Innovation, our breakthrough technology delivers clean extracts for your applications. Unlike conventional organic solvent extraction methods that may require dry and ground source materials, the PhytoClean™ Method can process a wide variety of plant materials of varying moisture contents, whether you are extracting bioactives from dry tea or a moist berry pomace.

Available as standardized extracts, or tailored to meet specific formulation requirements, PhytoClean™ ingredients can be incorporated into a wide range of functional foods, dietary supplements, and beauty products. Our growing portfolio of clean, high-quality extracts can meet the growing consumer demand for clean label products.

PHYTOCLEAN™ LAB & MANUFACTURING SITE

We produce high-quality bioactive extracts in our PhytoClean™ Manufacturing facility, located in Delta, BC. The facility showcases the equipment and technologies that comprise the PhyoClean™ method and processes a wide range of biomasses, including berries, grains, herbs, and teas.

Unlike conventional solvent-based extraction methods that require an explosion-proof facility, our green Phytoclean™ Method requires only a light manufacturing facility and no specialized hazardous waste management processes or waste disposal sites. Our environmentally-responsible facility has a low carbon footprint while producing ingredients of the highest quality.